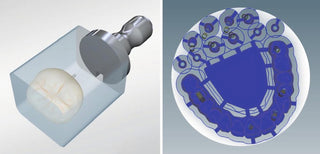

The advent of advanced technologies continues to revolutionize dentistry, with the Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) system standing out. The system leverages computer technology to design and fabricate dental restorations with remarkable precision and efficiency. Integral to the successful implementation of this technology is the strategic selection of suitable materials. This article provides a comprehensive overview of materials used in the CAD/CAM process for dental restorations.

Ceramics as CAD/CAM materials

1. Zirconia: Zirconium dioxide, commonly known as zirconia, is a durable, esthetically pleasing material that offers excellent biocompatibility. Resistant to wear and tear, zirconia is an ideal choice for fabricating crowns, bridges, and implant abutments. It can be pre-shaded or colored after milling to mimic natural teeth.

2. Lithium Disilicate: Lithium disilicate glass-ceramics are high-strength materials designed for anterior and posterior tooth restorations. Their strength and optical qualities make them an excellent choice for both crowns and veneers. They can be cemented traditionally or adhesively bonded depending on the clinical situation.

Polymers as CAD/CAM materials

1. Composite Resins: CAD/CAM composite resins offer a blend of aesthetics and durability. Available in a range of shades, they allow private practices to deliver same-day, natural-looking restorations. They are ideal for inlays, onlays, and partially bonded crowns.

2. Poly(methyl methacrylate) (PMMA): CAD/CAM PMMA is an acrylic glass that offers temporary and long-term provisional restorations. PMMA restorations can serve up to a few months, providing an affordable and aesthetically acceptable result for patients while their definitive indirect restorations are created.

Metals as CAD/CAM materials

1. Titanium: Titanium is a material of choice for implant restorations due to its superior strength and biocompatibility. Its resistance to corrosion ensures the longevity of the restorations.

Hybrid materials

1. Ceramic-resin hybrids: Such materials integrate the properties of ceramics and composite resins, thus providing a balance of strength, flexibility, and aesthetics. Their ability to mimic the translucency of natural teeth makes them ideal for both anterior and posterior restorations.

Considerations when choosing materials for CAD/CAM

Dentists need to consider various factors when selecting the appropriate CAD/CAM material for restorations, including the location and function of the restoration (anterior or posterior), patient's occlusion, aesthetic requirements, and the patient’s oral hygiene habits, allergies or sensitivities, and financial constraints.

Importantly, the material chosen should have sufficient strength to withstand occlusal pressures, be biocompatible with oral tissues, and have good resistance to degradation in an oral environment. Additionally, it should provide the dentist with the desired handling properties and the patient with the required aesthetics.

Conclusion

The use of CAD/CAM technology in dentistry has revitalized the landscape of dental restorations. From ceramics to polymers, metals, and hybrids, numerous materials can be machined using CAD/CAM technology to suit a variety of dental applications. The ever-growing advancement in CAD/CAM technology, along with the advent of novel materials, continues to enable dental practitioners to combine functional efficiency with outstanding aesthetics, promising optimum results for every dental restoration procedure. Despite the differences, as technology advances, the materials mentioned above will continue to be finessed, with their properties enhanced to ensure even better, more precise, and more aesthetic restorations.